Vending Machine Motor Jams: Understanding How to Resolve the Issue

Motor jams are one of the most frequent and disruptive problems that vending machine operators encounter, and they can quickly turn a reliable machine into a source of frustration for both customers and businesses. A motor jam occurs when the motor responsible for dispensing products becomes stuck or blocked, preventing the machine from delivering items as intended. Because vending machines are often placed in high traffic areas where customers expect quick and seamless service, even a short period of downtime can lead to lost sales and diminished trust. For operators, understanding the causes of motor jams, how to prevent them, and the best strategies for resolving them is essential to maintaining smooth operations and protecting revenue.

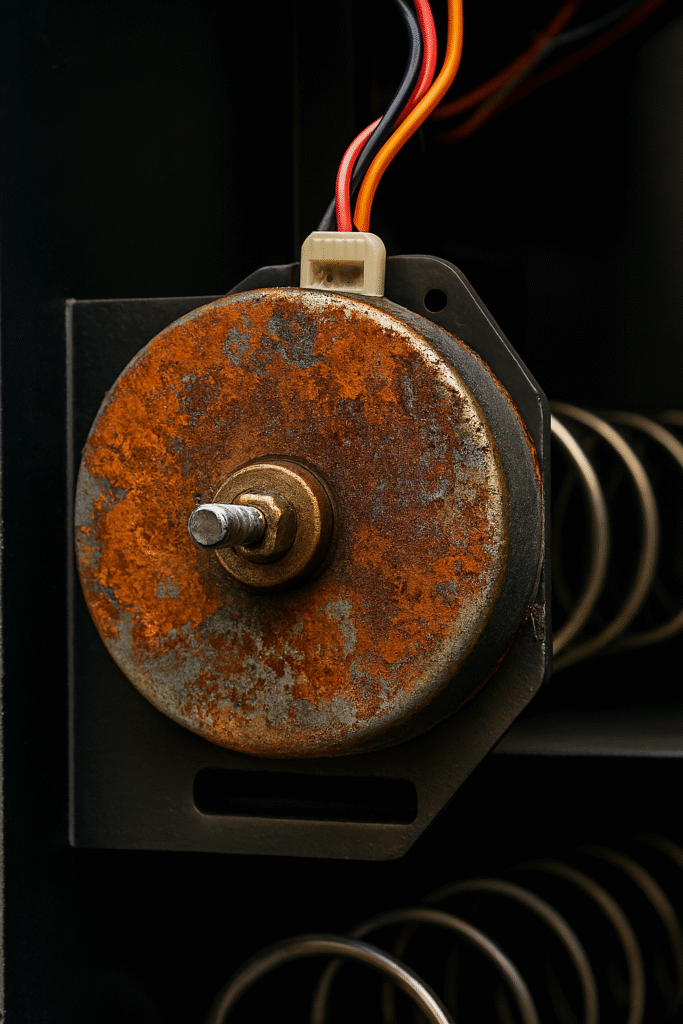

The causes of motor jams are varied, but they usually fall into a few key categories. Product misalignment is one of the most common issues. If items are not loaded correctly or are packaged in a way that makes them difficult to dispense, they can become stuck in the spiral or coil, forcing the motor to stall. Overloaded coils or spirals are another frequent culprit. When too many items are placed in a single slot, the motor has to work harder than it was designed to, which can lead to jams or even mechanical failure. Foreign objects also pose a significant risk. Packaging debris, coins, or other obstructions can block the motor from functioning properly, causing it to seize up. Finally, motors that have worn out due to age or heavy use may fail to rotate correctly, resulting in repeated jams and the need for replacement.

Preventing motor jams begins with careful product loading and consistent maintenance. Operators should ensure that items fit the machine’s dispensing mechanism correctly and avoid overfilling spirals or coils. Regular inspections of the motor and associated components are essential to catch signs of wear or mechanical stress before they lead to failure. Keeping the vending machine clean and free of debris reduces the risk of foreign objects interfering with the motor. For machines in high traffic locations, preventive care is even more important, as frequent use increases the likelihood of jams. Many operators are now turning to smart vending technology with sensors that can detect dispensing errors or motor strain before they become critical issues. These systems provide alerts that allow operators to intervene quickly, reducing downtime and preventing customer dissatisfaction.

When a motor jam does occur, quick resolution is key to minimizing lost sales. The first step is to turn off the machine to prevent further damage. Operators should then remove the obstructed product and inspect the motor for any signs of damage or wear. Following manufacturer instructions is important to ensure that the jam is cleared safely and without causing additional harm to the mechanism. In cases of persistent jams or motor failure, replacement of the motor or related components may be necessary to restore functionality. Having spare parts on hand can make this process faster and reduce downtime. Prompt action not only maintains customer satisfaction but also protects revenue by keeping machines operational.

Upgrading to modern vending machines with durable motors and advanced anti jam mechanisms can significantly reduce the frequency of motor jams. These machines are designed to handle a wider variety of products and include features that minimize the risk of misalignment or overload. Smart vending machines with remote monitoring and telemetry take this a step further by allowing operators to receive alerts when a motor is struggling. This proactive approach enables faster intervention and maintenance, ensuring smoother operations and reducing downtime. For operators managing multiple machines across different sites, remote monitoring is especially valuable, as it eliminates the need to rely solely on customer complaints to identify issues.

Motor jams are not just a technical problem; they directly affect the customer experience. A customer who encounters a jam may lose confidence in the machine and choose not to use it again. In competitive environments where multiple vending options are available, this can lead to lost business. By keeping machines well maintained and equipped with modern technology, operators can ensure that customers enjoy a smooth, reliable transaction every time. This builds trust and encourages repeat use, which is essential for long term profitability.

The environment in which a vending machine operates also plays a role in the likelihood of motor jams. Machines in busy public spaces are more likely to encounter issues due to heavy use and the variety of products stocked. In these locations, investing in higher quality motors and advanced monitoring systems is often worth the cost. Machines in controlled environments, such as offices or schools, may experience fewer problems but still benefit from regular cleaning and inspections. Tailoring maintenance schedules and equipment choices to the specific environment helps operators manage risk more effectively.

Looking ahead, vending machine motors are expected to become even more reliable as technology advances. Future innovations may include motors with self diagnostic capabilities, improved durability, and integration with AI driven monitoring systems that predict failures before they occur. As sustainability becomes more important, operators may also see machines designed to reduce energy consumption while maintaining consistent performance. Staying current with these advancements will help operators reduce downtime, lower costs, and maximize revenue.

FAQ: Vending Machine Motor Jams

Q1: What causes motor jams in vending machines?

A: Common causes include product misalignment, overloaded coils or spirals, foreign objects, and worn or faulty motors.

Q2: How can I prevent motor jams?

A: Load products correctly, avoid overfilling spirals, regularly inspect and maintain the motor, and keep the machine clean and debris free.

Q3: What should I do if a motor jam occurs?

A: Turn off the machine, remove the obstructed item, inspect the motor, and follow manufacturer instructions to clear the jam safely.

Q4: Can smart vending machines help prevent motor jams?

A: Yes. Machines with sensors and telemetry can alert operators to motor strain or dispensing issues before a jam occurs, allowing for quicker resolution.

Q5: How often should I maintain motors to prevent jams?

A: Regular maintenance every 1–3 months, depending on machine usage, helps ensure the motor functions smoothly and reduces the likelihood of jams.

Effectively managing vending machine motor jams is crucial for keeping machines operational, ensuring customer satisfaction, and protecting revenue. By understanding the common causes, implementing preventive maintenance, resolving jams promptly, and using modern vending technology, operators can minimize downtime and maintain reliable vending operations. As vending technology continues to evolve, those who invest in proper care and modern systems will be better positioned to thrive in the competitive vending industry.

Snack Vending Machines: A Complete Guide for Operators

Snack vending machines are a staple in the vending industry, providing convenient…

Vending Machine Telemetry and Remote Monitoring: A Complete Guide

In today’s competitive vending industry, telemetry and remote monitoring…

Vending Machines in Hotels: A Complete Guide for Operators

Placing vending machines in hotels presents a unique and profitable opportunity …