Vending Machine Stocking: Tips, Best Practices, and FAQs

Proper stocking of vending machines is one of the most important aspects of running a successful vending business. It directly impacts sales, customer satisfaction, and the overall efficiency of operations. Whether you manage snack machines, beverage machines, or specialty units, knowing how to stock effectively, track inventory, and select the right products can make the difference between a machine that thrives and one that struggles. Customers expect convenience, freshness, and variety, and operators who understand how to deliver these consistently are the ones who build long term profitability.

The first step in stocking successfully is understanding your location and audience. Every environment has its own unique customer preferences, and tailoring your product mix to match those preferences is essential. Machines in office settings often perform best when stocked with coffee, bottled water, and healthier snack options that appeal to professionals looking for quick energy during the workday. Gym machines, on the other hand, benefit from protein bars, sports drinks, and hydration focused products that align with fitness goals. Schools and universities tend to see strong demand for affordable snacks and drinks that appeal to students, while hotels and apartment complexes may require a broader mix to satisfy diverse guests and residents. Conducting a location analysis and tracking sales trends over time helps operators refine their product selection and ensure machines are stocked with items that meet demand.

Organizing products for efficiency is another critical part of stocking. Customers are more likely to make repeat purchases when machines are easy to navigate and visually appealing. Grouping similar items together creates a logical flow, while placing high demand products in accessible positions ensures they are easy to find. Proper spacing is also important, as overcrowding coils or spirals can lead to jams and dispensing errors. Rotating products regularly reduces the risk of expiration or spoilage, and clear labeling helps customers quickly identify what they want. A well organized machine not only improves the customer experience but also reduces maintenance issues for operators.

Inventory tracking and restocking schedules are vital for maintaining uptime and maximizing sales. Smart vending machines equipped with telemetry allow operators to monitor stock levels remotely, track best selling items, and schedule restocking efficiently. This technology provides real time insights into product performance, helping operators adjust inventory based on demand. For machines without telemetry, creating a consistent restocking schedule based on sales patterns is essential. Weekly checks are common, but high traffic locations may require more frequent visits. Seasonal trends should also be considered, as certain products perform better at specific times of the year. For example, cold beverages may sell more during summer months, while hot drinks and comfort snacks may see higher demand in winter.

Preventing spoilage and waste is critical for both profitability and compliance. Beverages and perishable items should always be checked for expiration dates, and stock should be rotated using the “first in, first out” method to ensure older products are sold before newer ones. Refrigerated machines require proper temperature management to maintain product quality, while dry machines should be kept clean to prevent contamination and maintain hygiene standards. Operators who neglect these practices risk not only losing revenue but also damaging customer trust. A spoiled product can discourage repeat purchases and harm the reputation of the vending business.

Another important aspect of stocking is balancing product variety with profitability. While it is tempting to offer a wide range of items, operators must focus on stocking products that sell consistently. Tracking sales data helps identify best sellers and eliminate underperforming items. Offering a mix of affordable staples alongside premium options allows operators to cater to different customer preferences. Limited time products or seasonal offerings can generate excitement and encourage customers to try something new, but they should be introduced strategically to avoid waste.

Technology continues to play a growing role in vending machine stocking. Smart vending machines not only provide telemetry data but also allow for advanced features such as dynamic pricing, targeted promotions, and loyalty programs. These tools help operators maximize revenue by tailoring product offerings to customer behavior. Remote monitoring also reduces the need for unnecessary service trips, saving time and labor costs. By leveraging technology, operators can streamline stocking processes and ensure machines remain profitable.

Ultimately, effective vending machine stocking is about consistency and attention to detail. Customers expect machines to be reliable, and operators who prioritize proper stocking practices build trust and encourage repeat business. By understanding location specific preferences, organizing products efficiently, tracking inventory, and implementing preventive measures, operators can create a streamlined and profitable vending operation that stands out in a competitive market.

FAQ: Vending Machine Stocking

Q1: How often should I stock my vending machines?

A: Restocking frequency depends on location and sales volume, but most operators check machines weekly. High traffic locations may require more frequent visits.

Q2: How do I choose the best products for my vending machine?

A: Consider your location, audience demographics, and sales trends. Offering a mix of popular snacks, beverages, and specialty items helps maximize revenue.

Q3: How can I prevent product spoilage?

A: Rotate stock using FIFO, monitor expiration dates, maintain proper temperatures for refrigerated machines, and restock regularly.

Q4: Can smart vending machines help with stocking?

A: Yes. Telemetry enabled machines provide real time stock levels, identify best sellers, and allow operators to schedule restocking efficiently.

Q5: How should products be organized in a vending machine?

A: Group similar items together, place high demand products in accessible locations, and ensure adequate spacing to prevent jams in coils or spirals.

Effective vending machine stocking is a cornerstone of success in the vending industry. By combining thoughtful product selection, efficient organization, consistent inventory tracking, and modern technology, operators can reduce downtime, maximize sales, and deliver a positive customer experience. As vending continues to evolve, those who master stocking practices will remain competitive and profitable in the long run.

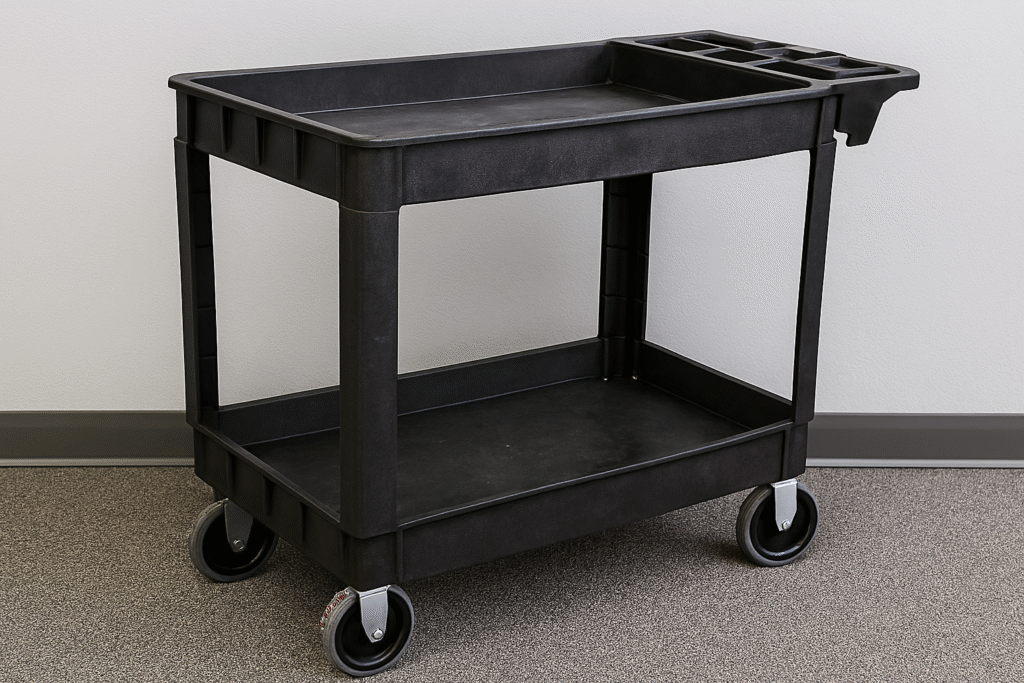

Vending Carts: The Complete Guide for Vending Machine Operators

For vending machine operators, vending carts are an essential tool…

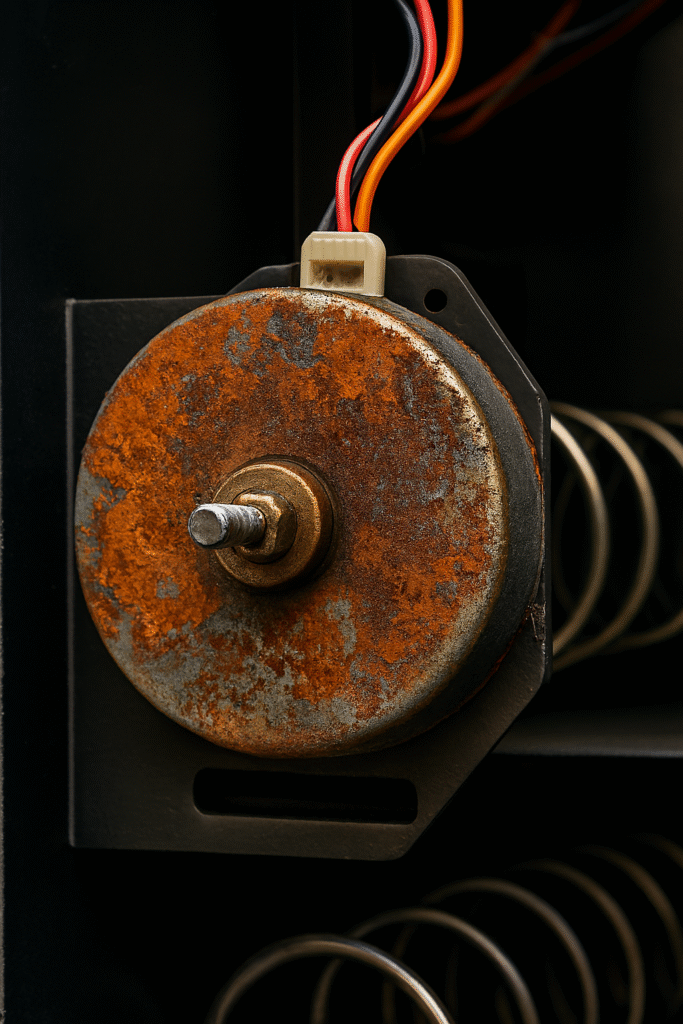

Vending Machine Motor Jams: Causes, Prevention, and Solutions

Motor jams are a common issue for vending machine operators and can significantly…

Selectivend Advantage Plus Vending Machine Review: Is It Right for Your Combo Route?

Vending operators who need both snacks and beverages from a single…